Background

A distillery in NSW wanted to reduce Biochemical Oxygen Demand (BOD) in the trade waste discharge. The current method of flocculation did not reduce the BOD to below acceptable limits of 230kg/day (MDM). The client approached Water Treatment Services (WTS) to take samples and look at the chemistry for a solution.

WTS was engaged to conduct initial jar test and plant trial to reduce the BOD in trade waste discharge.

WTS solution

WTS collected samples from the trade waste tank prior to the effluent entering Dissolved Air Flotation (DAF) and conducted a Jar test with WTS coagulant/flocculant and chlorine dioxide. The Jar Test report was submitted, and the client allowed to conduct plant trials with WTS coagulant/flocculant/chlorine dioxide and dosing pumps.

- Collection, analysis and testing of water samples

- Collection, analysis and testing of trade waste samples

- Jar testing of trade waste samples with various treatment chemistry combinations

- Plant trial using WTS coagulants/flocculants and chlorine dioxide

- NATA Lab testing for BOD samples for trade waste discharge during plant trial.

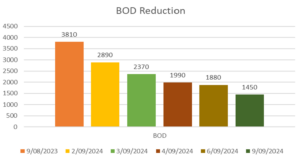

BOD Reduction during the trial

|

|

| Plant trial with WTS coagulants/flocculants/chlorine dioxide dosing | Plant trial with WTS coagulants/flocculants/chlorine dioxide dosing |

Results and Benefits

- Compliance Achieved required standard of discharge as per Sydney Water Corporation (SWC) Trade Waste Requirements

- Easy to operate Dosing system and day tank was set up with bespoke chemistry solutions for ease operation of the plant trial.

- Reduce sludge Sludge coming out of the centrifuge was much drier as compared to previous treatment.

- Savings Cost reduction in discharge compliance and sludge disposal costs.