WTS Coal Handling and Preparation Plant Corrosion Mitigation

Background

A Yancoal open cut Coal mine, Handling, Preparation & Processing plant (CHPP), located in Central Queensland’s Bowen Basin produces ultra-low volatile, semi-anthracite for Pulverised Coal Injection, exporting to steelmakers in the Asian region via the port of Gladstone. Their operations were faced with high ongoing maintenance costs from severe corrosion due to using “mine water” for processing purposes. This water was found to have high levels of sulphate and chlorides with a conductivity of 16,000µs/cm. WTS analysed and modelled various waters collected at several points through the process infrastructure to develop a solution to reduce their corrosion problem.

Problem

Yancoal’s CHPP was faced with high ongoing maintenance costs from severe corrosion due to using mine water for processing purposes. This water was found to have high levels of sulphate and chlorides with a conductivity of 16,000µs/cm.

Solution

Computer modelling indicated two possible products, both of which were bench trialled. These results indicated that dosing the feed water with the corrosion inhibition product WTS 5-0017 at 10 ppm would significantly reduce mild steel corrosion.

WTS Key Solutions

- Plug and play” dosing and monitoring skid

- Online monitoring of corrosion, pH, conductivity and ORP

- Dosing of WTS 5-0017 for corrosion mitigation

- 4 x corrosion coupon racks for monitoring at multiple points

- Pressure sustaining pump for carry-water

- Weekly online report

- Onsite service

- Offsite analysis of corrosion coupons

Results & Benefits

- Corrosion Mitigation. WTS 5-0017 produced a ~50% reduction in corrosion rates at 1ppm!

- Savings. Corrosion related maintenance spend approx. AUD 1 million per annum now just AUD 60,000/yr of Corrosion mitigation treatment

- Industry Standard. Approaching 5 MPY, industry best practice for corrosion.

- Technical Support. Expert advice and consultation with all parties throughout the process and ongoing service and optimisation by WTS.

- 24 hrs online access. Online and continuous corrosion monitoring allowing for real time changes and full historical analysis.

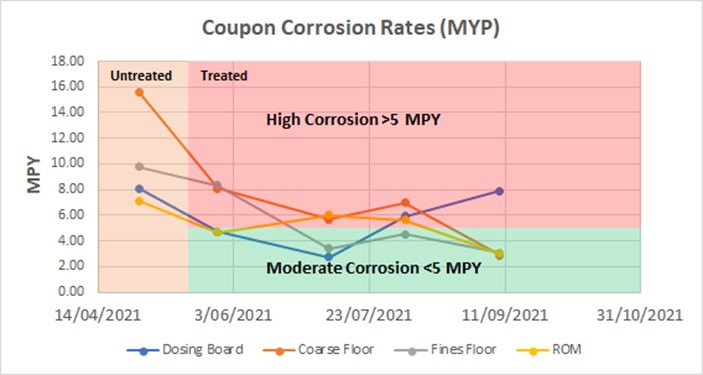

Coupon Corrosion Results

- 4 corrosion coupon monitoring locations:

- Dosing board

- Coarse floor

- Fines floor

- ROM

- Corrosion rates reduced at all locations

- Dosing rate at 1-2 ppm to achieve ~ 50% reduction in corrosion rate at 3 out of 4 locations

- Coarse floor corrosion reduced by ~ 80%

Online Corrator Corrosion Results

- Online corrator/corrosion monitoring

- Untreated corrosion detected up to 70 MPY

- WTS 5-0017 achieves less than 5 MPY (~3MPY)

Visual Coupon Results

- Obvious visual corrosion on baseline corrosion coupons

- Corrosion observed occurring <5min after installation on untreated system

- Treated corrosion coupons visually showed less corrosion and more uncorroded base metal