Background

A manufacturing plant in Melbourne processing synthetic and natural fibres for personal care products, faced several critical challenges with their process water system.

- Biofouling & Downtime: Frequent blockage of jet nozzles by biofouling debris led to excessive downtime and filter cleaning

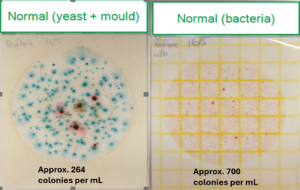

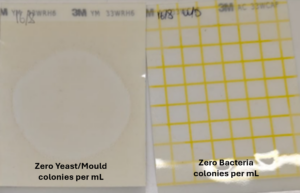

- Microbial Contamination: Elevated microbial counts in process water and finished products

- High Peroxide Consumption: Continuous dosing of approximately 1500 ppm Hydrogen Peroxide posed supply, logistical and safety challenges.

The client needed for a simple trial to validate a new sanitation technology without high capital equipment expenditure.

WTS solution

The WTS 7-CDS (pump and go Chlorine Dioxide Solution) was trialled. Prior to trial WTS experts confirmed H2O2 degradation of ClO2 and that the client’s process water system was well-suited for Chlorine Dioxide treatment.

The system was modelled to establish optimal dosing rates, ensuring a consistent residual Chlorine Dioxide level (0.2–0.3 ppm) throughout the system.

During a scheduled maintenance shutdown, the system was drained to flush out the residual Hydrogen Peroxide. The existing diaphragm dosing pump was repurposed to dose WTS 7-CDS, transitioning seamlessly from the previous chemical.

Continuous dosing was initiated to maintain a steady Chlorine Dioxide residual, effectively curbing biofouling and microbial contamination.

This approach allowed the client to transition to a more effective and safer sanitation system without any additional capital expenditure.

|

|

| Existing Peroxide system | WTS 7-CDS Chlorine Dioxide Solution |

|

|

| Biofilm pre WTS 7-CDS Chlorine Dioxide Solution | Biofilm post WTS 7-CDS Chlorine Dioxide Solution |

Results and Benefits

- Downtime Reduction:

74% fewer police filter blockages

19% improvement in bag filter blockages - Reduced biofouling:

Obvious reduction in biofouling via visual inspection on tanks and pipes - Improved Product Quality:

Near-zero microbial counts in finished products - Cost and Time Savings:

No new capital expenditure; rapid implementation using existing infrastructure - Operational Efficiency:

Simplified logistics by switching from Dangerous Goods to non-DG WTS 7-CDS.