background

The primary function of the water system in a typical mining operation circuit is to extract the target metal from the ore for later recovery in downstream operations. Water related problems can occur because of chemical (for example, lime) additions for efficient processing in high pH and calcium environments. Scale forming water from underground sources can also be a problem. Effective scale control programs improve the system’s efficiency, reduce maintenance and prevent shutdowns that impact production.

Accurate prediction of the tendency for scale formation, type of scale, most efficient inhibitor and dose rate is required due to the significant volume of water, cost of treatment and consequences of scale formation. As a result, the successful inhibitor programs must be capable of preventing scale formation at low dosages and should be predictable so that modifications can be made as changes occur in water chemistry.

solution

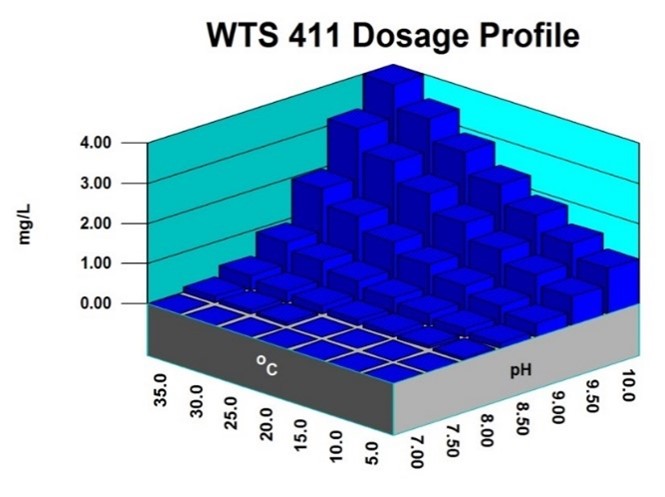

WTS uses French Creek Minesat predictive software to model all aspects of the system and predict which inhibitor is most suited to the operation. In many cases, synergistic blends are created specifically to address the types of scale present. Dose rates for varying conditions and different scale can be accurately predicted.

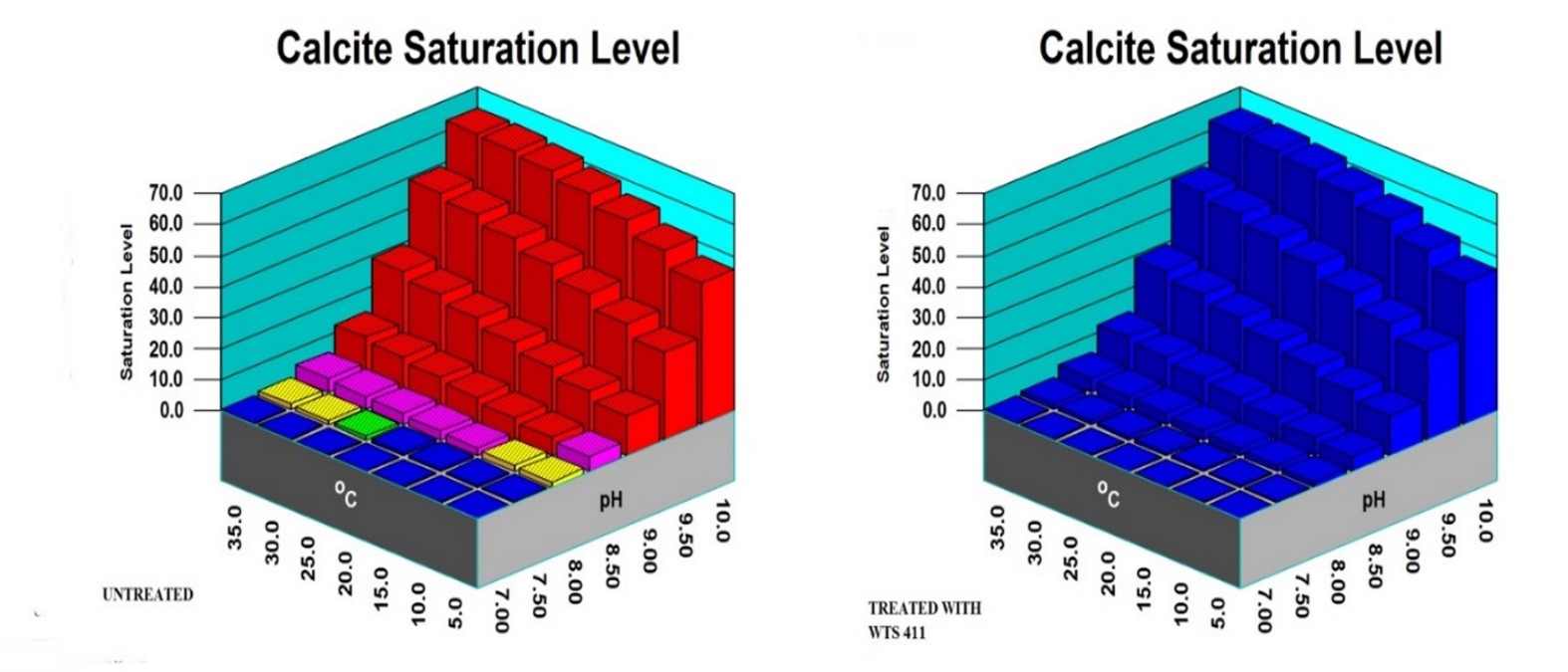

- RED –Scale and loss of control

- Magenta –problem is highly likely.

- Yellow problem will occur with minor change

- Green –No problems likely Blue-Safe operation.

The above graphs show that, under the predicted conditions, that the scale can be controlled at all pH levels and temperatures that the system may encounter.

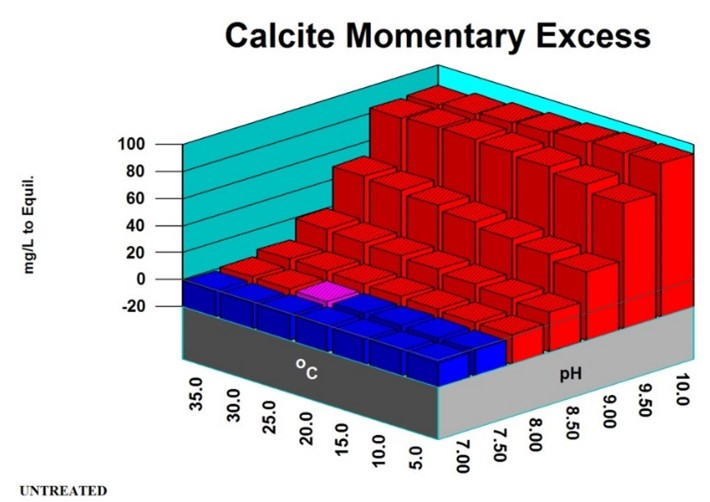

If control is lost, then WTS can also predict how much scale can potentially be precipitated by graphing the momentary excess or the amount of calcite in solution above the saturation point. For example, at pH 9.5 and 35°C the momentary excess is 80 mg/litre, so this is the amount that will precipitate to get to a saturation level of 1 where the calcite is soluble at that temp and pH. If the system volume is 1 ML then this would equate to 80 kg of scale.

The dose rate for any of the conditions evaluated can be predicted as shown in the dosage profile. Therefore, the treatment strategy will ensure safe operation at all times.

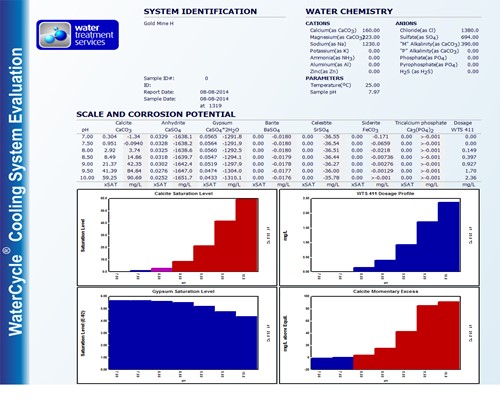

A comprehensive report, such as the example below for a gold mining client, can be generated showing saturation levels of the scale forming species determined by the chemistry of the water. Varying the conditions allows us to look at “what if” and avoid any problems due to temperature or pH changes.

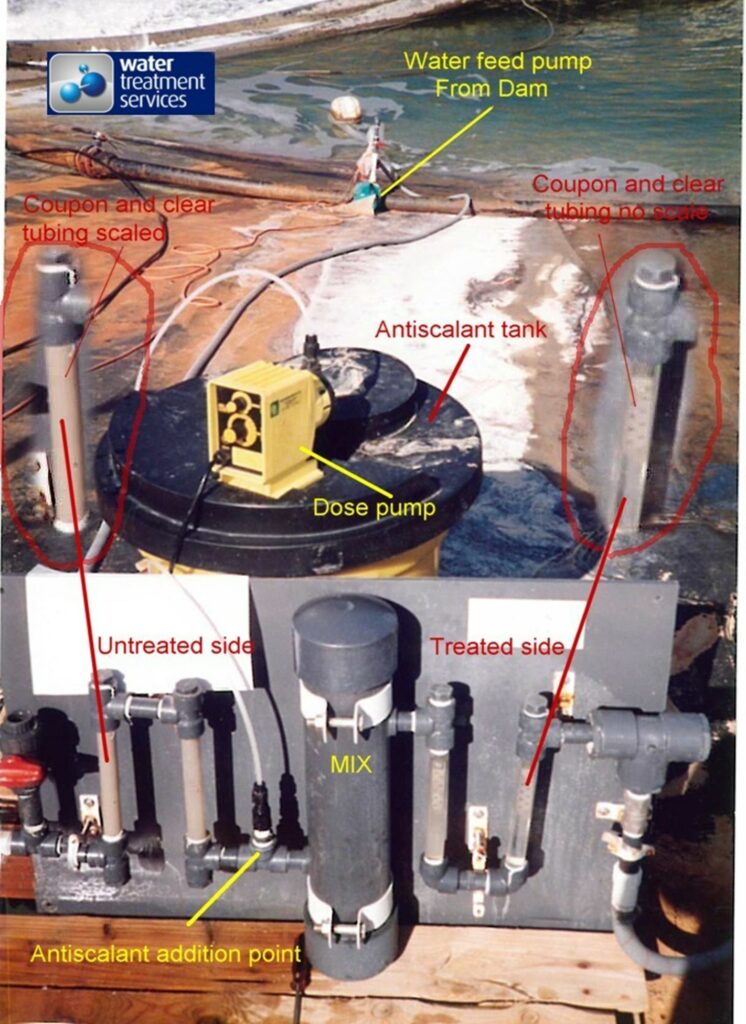

WTS can also provide a side stream scale rig which will allow “before and after” treatment comparisons. This can allow optimisation of dose rate. The mix unit can be changed to allow different residence times which can be a significant factor in large systems.

Rapidly deployable scale test rig

results and benefits

- Reliability. Reduced scale reduces likelihood of blockages and breakdowns

- Operational efficiency. Scale-free systems flow as intended without obstruction

- Consumables Efficiency. Tailored solution ensures optimal consumption.

- Visual confirmation. Side stream scale rig indicates “before and after” treatment comparisons